Enerdyne Solutions Polara™ heat spreader is a revolutionary advance in ambient cooling that offers higher performance at reduced solution cost over competing approaches. Polara serves both general electronics cooling needs and the more specific problem of hot spot mitigation. Not only does Polara offer higher performance at reduced cost but it also competes effectively on the basis of enabling solutions that are lighter, smaller, and quieter.

No other cooling technology available today offers Polara’s unique combination of features and benefits:

- Less than 1/3 the cost of AlSiC, Cu-Mo and Cu-W composite spreaders

Depending on application specifics and production volumes, Polara can cost as little as $1 per square inch. With its increased performance additional solutions savings can be readily achieved in other components, notably the heat sink and fan.

- CTE matching Silicon or Gallium Arsenide (GaAs) allowing direct eutectic attach

Polara is a semiconductor-based product, and can be built with a Coefficient of Thermal Expansion (CTE) to closely match the chip to be cooled. This allows the use of economical and conventionally deployed solders with high thermal conductivities, and eliminates the need for thermally resistive TIMs. With a big reduction in thermal resistance the demands on heat sinks and fans are relaxed, leading to many desirable results: decreased costs, quieter operation, and form-factor reductions.

- Electrical isolation, grounding and EMI shielding

Polara can be readily customized to the specific needs of your application, including metallization or the addition of dielectric layers.

- Discrete, package or die-level integration options

Polara offers flexible deployment options. A discrete component has the simplest design-in process, and can be solder-attached for excellent performance. Polara can also replace the integrated heat spreader in a package. For highest performance Polara Thermal Raceways technology is integrated directly into the chip design.

- Anisotropic heat transfer using Thermal Raceways™ for maximum cooling efficiency

Most hot electronic components are not uniform, but instead have localized areas, or hotspots, of greater heat-flux density. Conventional heat spreaders or other thermal solutions cannot take advantage of this, and so waste performance on relatively cool regions of the chip in order to handle the hottest areas. The emerging trend towards chips with multiple processors, or multiple cores, has temporarily reduced the hotness of some hotspots. The increasing number of such cores on each chip will, however, add to the total heat problem as well as increasing the variations of heat flux density within a chip, increasing the demands on the cooling solution.

- Hot spot mitigation performance equivalent to diamond composite heat spreaders

Thermal Raceways are powerful heat spreader features unique to Polara. Using a revolutionary implementation of the Peltier effect, Enerdyne Solutions has created a device that actively pumps heat from hotter to cooler regions. These heat-transporting raceways are both highly efficient and have such incredibly high effective thermal conductivity that they provide hot spot temperature reductions previously possibly only with costly diamond composites.

- Smart Spreading™ with passive thermal conduction and active heat pumping

Enerdyne has the industry's only true anisotropic heat spreader, allowing die-level customization of the solution, and hence, better price and performance. Learn more technical detail about Enerdyne's Smart Spreader by downloading the PDF: "Cooling Microelectronics with Thermal Raceways", a paper presented at the IMAPS Advanced Technology Workshop Thermal 2003.

- Built and deployed using standard manufacturing and assembly processes.

Polara fabrication requires neither a clean room nor highly polished and expensive silicon wafers. Second-sourcing is not an issue as many large and established manufacturers have had the equipment and know-how for years. Polara’s highly cost-effective performance is partly due to these well-understood and long-used processes and materials.

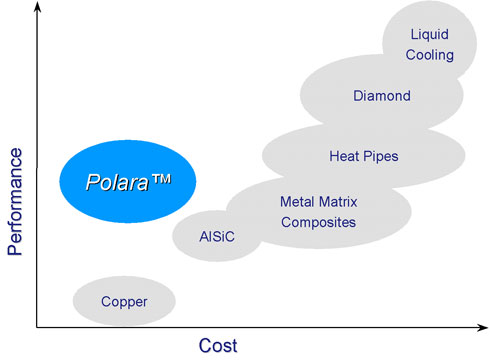

Enerdyne Solutions Polara offers superior price-performance characteristics compared to the available alternatives:

All of these solutions lie generally in a straight line; higher performance comes at consistently defined higher cost. While other technologies offer higher performance, the cost is correspondingly greater. Polara is less costly than alternatives of comparable cooling performance, and more powerful than alternatives of comparable cost.

Polara can provide many advantages and benefits to customers, including enabling production of otherwise unviable products, saving money by reducing the build cost of existing products, and providing meaningful differentiation of products that leads to bankable competitive advantage. The higher performance of Polara, especially at the edges of the device, permits the use of smaller and cheaper heat sinks and fans, reducing costs and form factor.

|

|

Ordinary heat spreader

Passive heat conduction only |

Enerdyne Solutions Polara

Passive heat conduction & active heat pumping |

The solid-state construction of Polara offers better reliability and lower cost than heat pipe, MEMS, and exotic liquid cooling solutions. Polara allows the increase of gross margins by reducing COGS, or the offering of product at a lower price while maintaining margins. Polara spreads heat more efficiently to the heat sink, and more closely matches the thermal expansion of the chip than competing technologies. This permits the construction of higher-performance systems of faster clock speeds and greater power consumption, meeting demand for end users’ growing computational power. The smaller size and lighter weight of Polara allows increased design flexibility, and more truly portable appliances since it solves present design barriers to advancing integrated circuit miniaturization and complexity. Manufacturers can increase market share because of these advantages by offering a product with superior characteristics their customers demand.