|

|

|

|

|

|

|

|

|

|

|

|

Polara

Enerdyne Solutions’ Polara™ technology is a package-level heat spreader designed to be solder bonded to a high flux, thermal expansion (CTE) matched die. Unlike conventional passive heat spreaders, Polara’s heat transfer occurs with two thermal mechanisms: Passive thermal conduction and active heat pumping through the novel use of Peltier Assisted Conduction (PAC).

Enerdyne Solutions’ Polara™ technology is a package-level heat spreader designed to be solder bonded to a high flux, thermal expansion (CTE) matched die. Unlike conventional passive heat spreaders, Polara’s heat transfer occurs with two thermal mechanisms: Passive thermal conduction and active heat pumping through the novel use of Peltier Assisted Conduction (PAC).

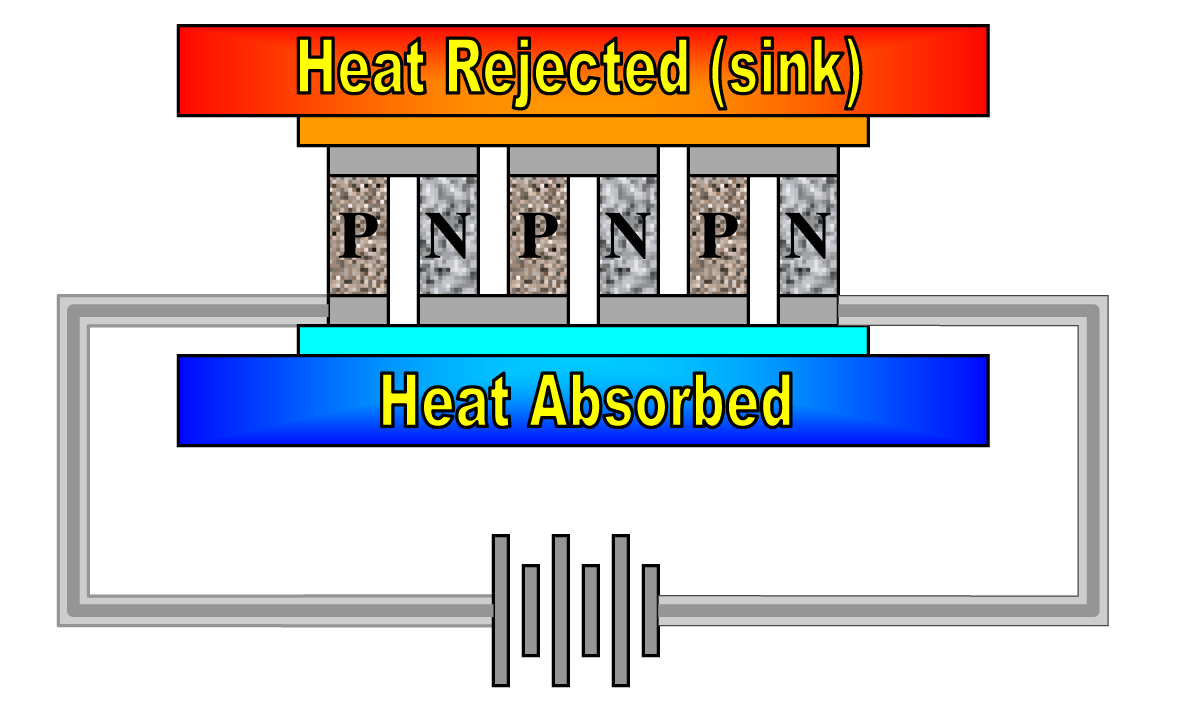

Conventional Thermoelectric Cooler

In conventional thermoelectric/peltier coolers, a current flowing through a circuit comprised of dissimilar conductors or semiconductors will cause an absorption (pumping) of heat energy at one junction and liberation of the absorbed energy at another. Designed to cool below ambient temperature, conventional thermoelectric or Peltier heat pumps are comprised of semiconductors of low thermal conductivity.

In conventional thermoelectric/peltier coolers, a current flowing through a circuit comprised of dissimilar conductors or semiconductors will cause an absorption (pumping) of heat energy at one junction and liberation of the absorbed energy at another. Designed to cool below ambient temperature, conventional thermoelectric or Peltier heat pumps are comprised of semiconductors of low thermal conductivity.

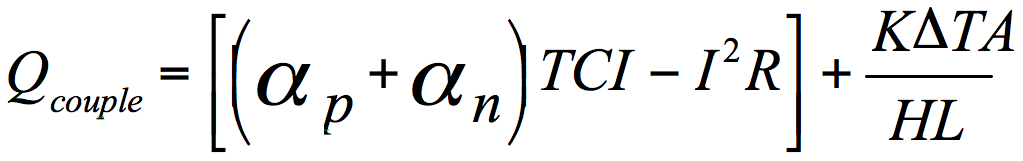

The Heat removal rate/efficiency is determined by thermoelectric properties, Joule losses, and passively conducted heat flowing counter to the direction of heat pumping:

Unlike conventional Peltier heat pumps, Polara is designed as heat spreader; to operate efficiently at equal to or greater than ambient temperature. Therefore, materials which possess relatively high thermoelectric properties and high thermal conductivities are utilized. The Heat removal rate/efficiency is determined by thermoelectric properties, Joule losses, and passively conducted heat thermally in parallel with pumped heat:

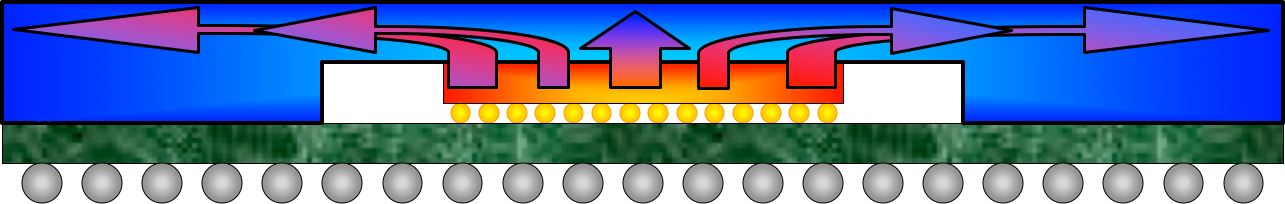

Polara heat spreader on BGA package

|

|

Polara may include multiple thermoelements, depending upon the specific heat flux and desired operating voltage. These oriented thermocouples are “Thermal Raceways”, tailored features to preferentially and anisotropically pump heat from the heat source interfacial surface and deliver it both thru-plane and in-plane with the Polara heat spreader and heat exchanger surface.

Polara technology potentially offers a unique combination of features and benefits:

- CTE matching Silicon or Gallium Arsenide (GaAs) allowing low impedance direct eutectic attach and reduced CTE related stresses

- Higher COP operation for reduced power consumption over conventional TECs

- Integration options: Discrete, package or die-level

- Anisotropic heat transfer for hot spot mitigation

Technology demonstrators have been fabricated. Learn more technical detail about Enerdyne's Polara technology by downloading the PDF: "Cooling Microelectronics with Thermal Raceways", a paper presented at the IMAPS Advanced Technology Workshop Thermal 2003.

|

|

|

|

|

|

|

|

|